Page 16 - Designing Ways 268

P. 16

PRODUCT

DESIGN

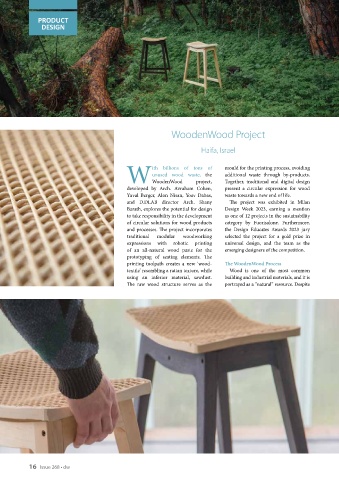

WoodenWood Project its potential for reuse, renewal, and wood weaving through robotic printing

biodegradability, the wood chain today is in order to prototype the WoodenWood a circular design expression of wood

far from circular, with millions of tons of seating elements. towards zero waste.

Haifa, Israel wood waste generated annually. The wood paste prepared for printing

D.DLAB's target is to create a is derived from Daika, sawdust with Technical Sheet

ith billions of tons of mould for the printing process, avoiding continuous lifecycle for wood by cellulose-based natural binders to enable • Company name: Disrupt.Design

unused wood waste, the additional waste through by-products. introducing a new approach to designing 100% biodegradability. A parametric Lab, The Technion Israel Institute of

WWoodenWood project, Together, traditional and digital design with waste materials. The WoodenWood model and manufacturing workflow are Technology

developed by Arch. Avraham Cohen, present a circular expression for wood project is a case study, a proof of developed to correlate between the chair • Design research team: SAY.research,

Yuval Berger, Alon Nisan, Yoav Dabas, waste towards a new end of life. concept. Its essence and main objective geometry, robotic toolpath, and material Arch. Avraham Cohen, Yuval Berger,

and D.DLAB director Arch. Shany The project was exhibited in Milan is to encourage a blending of traditional properties. Outputs are examined in Alon Nisan, Yoav Dabas and D.DLab

Barath, explores the potential for design Design Week 2023, earning a mention and advanced fabrication methods to relation to strength, elongation, visual Director Shany Barath

to take responsibility in the development as one of 12 projects in the sustainability combine into a workflow towards zero expression, and geometrical compatibility • Printing material: Daika Wood Ltd.

of circular solutions for wood products category by Fuorisalone. Furthermore, waste design. to customise human comfort. Through • Cinematography and Photography:

and processes. The project incorporates the Design Educates Awards 2023 jury The project addresses this challenge this process, numerous possible designs Haim Zinger and Arch. Avraham

traditional modular woodworking selected the project for a gold prize in by developing design methods in which can be explored to create a ‘one of a kind’ Cohen

expressions with robotic printing universal design, and the team as the traditional and digital craft are integrated chair within a mass production workflow. • Dimensions: Chair: 80cm x 60cm x

of an all-natural wood paste for the emerging designers of the competition. to convert wood waste, in the form of raw While the solid raw wood supports the 70cm, Stools: 50cm x 50cm x 70cm

prototyping of seating elements. The wood and sawdust, towards a new end of structure of the chair, the printed sawdust • Material: Oak, Maple and Daika wood

printing toolpath creates a new ‘wood- The WoodenWood Process life. Emerging from the tradition of fine completes the woven back and seat. The • Robotic Arm: UR5e collaborative

textile’ resembling a rattan texture, while Wood is one of the most common woodworking, the process combines the two lifecycles of raw wood and sawdust robot arm dw

using an inferior material, sawdust. building and industrial materials, and it is common expression of wood as a modular are combined through the fabrication of

The raw wood structure serves as the portrayed as a “natural” resource. Despite component to include the deposition of the WoodenWood chair, demonstrating www.ddlab.net.technion.ac.il

16 Issue 268 • dw dw • Issue 268 17